What is Compost?

Compost is organic material that can be added to soil to help plants grow.

What is Composting?

Composting is a natural process in which any organic material, such as food waste or grass clippings, is broken down by naturally occurring bacteria and fungi in the soil to form compost. Compost is a soil conditioner that is very similar to soil itself and is rich in nutrients. Composting can be done in almost any environment, from apartment buildings or community gardens to outdoor piles, and even in office areas where compostable materials are collected and transported to an external composting facility. Did you know that with our Aydınmaksan Branch Grinding and Shredding machines, tailored to your specific needs, you can easily compost in any area you desire?

What are the basics of composting?

All composting requires three basic components:

- Brown – Contains materials such as dead leaves, branches and twigs.

- Greens – Contains materials such as grass clippings, vegetable scraps and fruit scraps.

- Water – It is important to have the right amount of water, greens and browns for compost development.

Why are AYDINMAKSAN Branch Grinding/Shredding Machines important for a natural solution to increase soil fertility?

Composting reduces pollution, reuses organic waste, lowers the cost of fertiliser and agricultural inputs, and, most importantly, returns essential nutrients to the soil for food production. Your compost pile should have equal amounts of green and brown materials. You should also alternate layers of organic material consisting of particles of different sizes. Brown materials provide carbon for your compost, while green materials increase the nitrogen content, and finally, water provides moisture to help break down the organic matter.

With Aydınmaksan Branch Grinding Machines, you can easily turn all the materials you want to grind into compost, regardless of size and environment.

What Materials Can Be Composted?

- Hazelnut shells

- Garden decorations

- Lawn mowers

- Houseplants

- Leaves

- Sawdust

- Wood shavings

- corn husk

What are the benefits of compost?

- It enriches the soil, helps retain moisture, and suppresses plant diseases and pests.

- It reduces the need for chemical fertilisers.

- It promotes the production of beneficial bacteria and fungi that break down organic matter to form humus, a nutrient-rich material.

- It reduces methane emissions from regular storage areas.

One solution to increase soil fertility is to

Composting reduces pollution, reuses organic waste, lowers the cost of fertilisers and agricultural inputs, and, most importantly, returns nutrients necessary for food production back to the soil.

Composting enriches the soil with nutrients, which reduces the need for fertilisers and pesticides. Fertilisers and pesticides require fossil fuels for their production and transport, and some are potentially harmful to our health.

Compost improves the soil’s ability to retain moisture, helping to prevent erosion by reducing runoff. And compost prevents and suppresses plant diseases and pests. Moist and healthy soil improves soil workability.

Composting helps sequester carbon, meaning it contributes to removing carbon from the atmosphere.

How to Make Compost?

It is essential to maintain a balance of moisture and air for healthy compost. Therefore, you need to mix and aerate it every 3 days to a week. Choose the right location so that you can easily mix the manure and move around comfortably. Using a shovel, mix the outer parts of the pile inside the compost towards the inside and the inner parts towards the outside. To maintain moisture balance, you can slightly moisten the mixture if it dries out or add green material. If it becomes too wet, add brown material. Proper compost should have the consistency of a damp sponge.

Making cold compost takes time, as it can take at least 6 months. This timeframe may vary depending on climate conditions, the type and amount of materials used. For example, the composting process slows down in cold weather. For cold compost, you need to continuously add green and brown materials on top of each other. Once the bin is full, wait for it to compost. The key is to completely cover the materials with a carbon-rich material such as wood chips, straw, or dry leaves every time you add them. This prevents the compost from attracting pests and helps avoid unpleasant odours.

Hot composting is a quick method, but you may need to go through a trial and error process to get the right results. For this type of composting, you will first need a 1 cubic metre space and a thermometer. Before you start composting, make sure that all green and brown materials are finely chopped and readily available. Spread a shovel full of pre-existing compost or soil at the bottom of the bin. Then layer the materials you have, alternating one layer of brown and one layer of green, in 10-15 cm thick layers. Add accelerator materials such as rock dust or charcoal and water between the layers.

Hot compost reaches 49-77 degrees in the first few days, then drops below 43 degrees. At this point, it needs to be stirred to add oxygen. Stirring causes the compost temperature to rise again, and after a few days, it drops below 43 degrees again. If the compost does not heat up enough during hot composting, the nitrogen content may be insufficient. In this case, you can add green material. If it is overheating, the nitrogen content may be too high. In this case, you can turn it more frequently and add carbon-rich material. After about a month, if you mix it four times and let it sit, you will end up with dark-coloured compost of the desired consistency. The compost’s temperature is now below 29 degrees, and after two weeks of resting, it is ready for use.

How about using Aydınmaksan branch grinding machine in compost production?

At Aydınmaksan, we have developed advanced, superior technologies to leave a livable world for future generations. With our Branch Grinding and Shredding Machines, composting is now very easy.

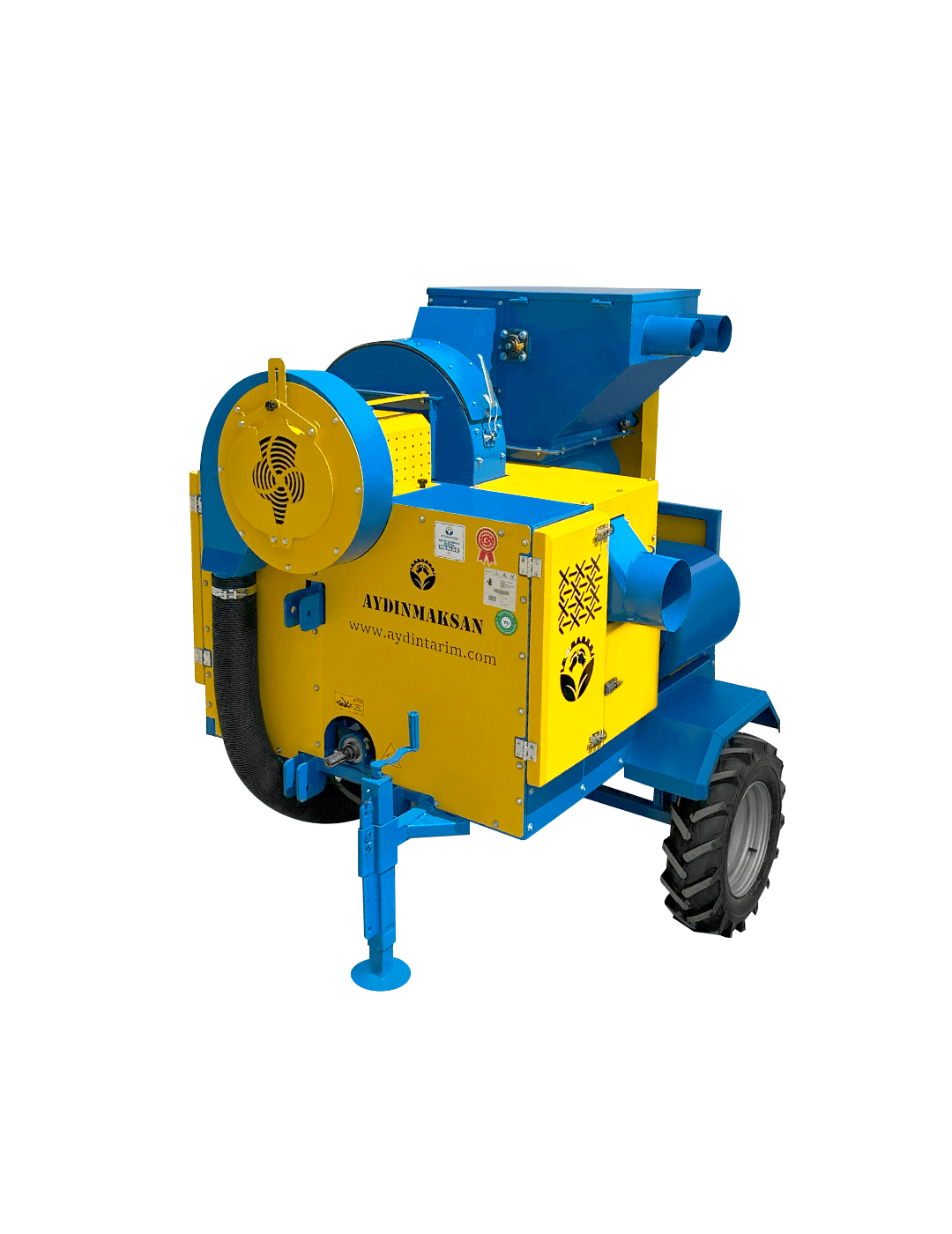

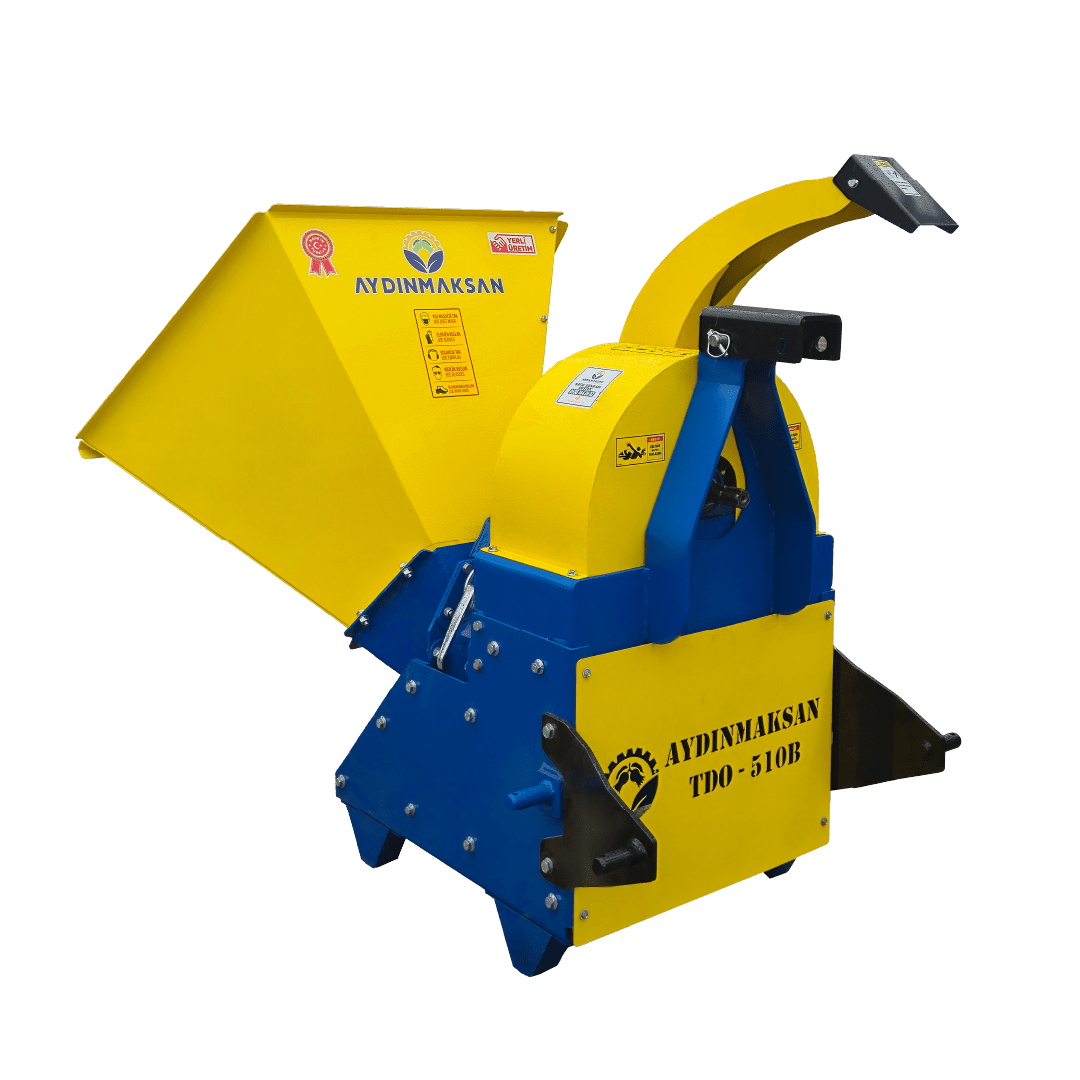

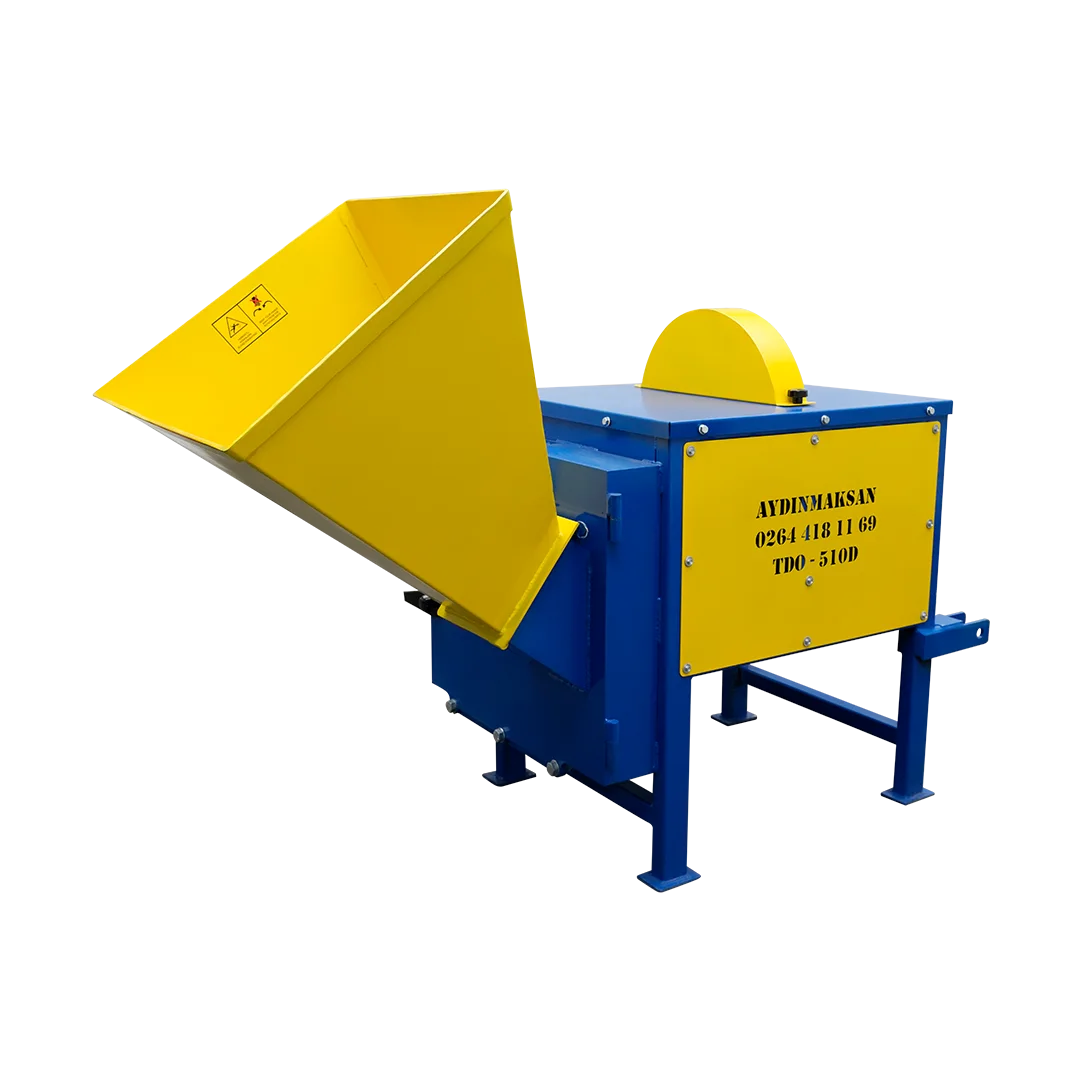

- Aydınmaksan Tractor-Mounted Branch Shredding Machine The machine shreds collected pruned tree branches, leaves, grass, and other waste into small pieces, turning them into wood chips. Thanks to the Tractor-Mounted Branch Shredding/Chipping Machine, the products obtained from the shredding of plant waste are left to ferment for 3-4 months and are then ready to be spread over the soil surface.

Our products;

- TDO 510A Tractor-Mounted Chimney-Free Branch Grinding Machine

- TDO 510B Tractor-Mounted Chimney-Type Branch Grinding Machine

- TDO 510D Tractor-Mounted Circular Saw Branch Grinding Machine

- TDO 700M Tractor-Mounted Banana Stem Grinding Machine

- TDO 700 Tractor-Mounted Chimney-Equipped Hydraulic-Driven Branch Grinding Machine

- TDO 700NS Tractor-Mounted Special System Driver-Operated Branch Grinding Machine

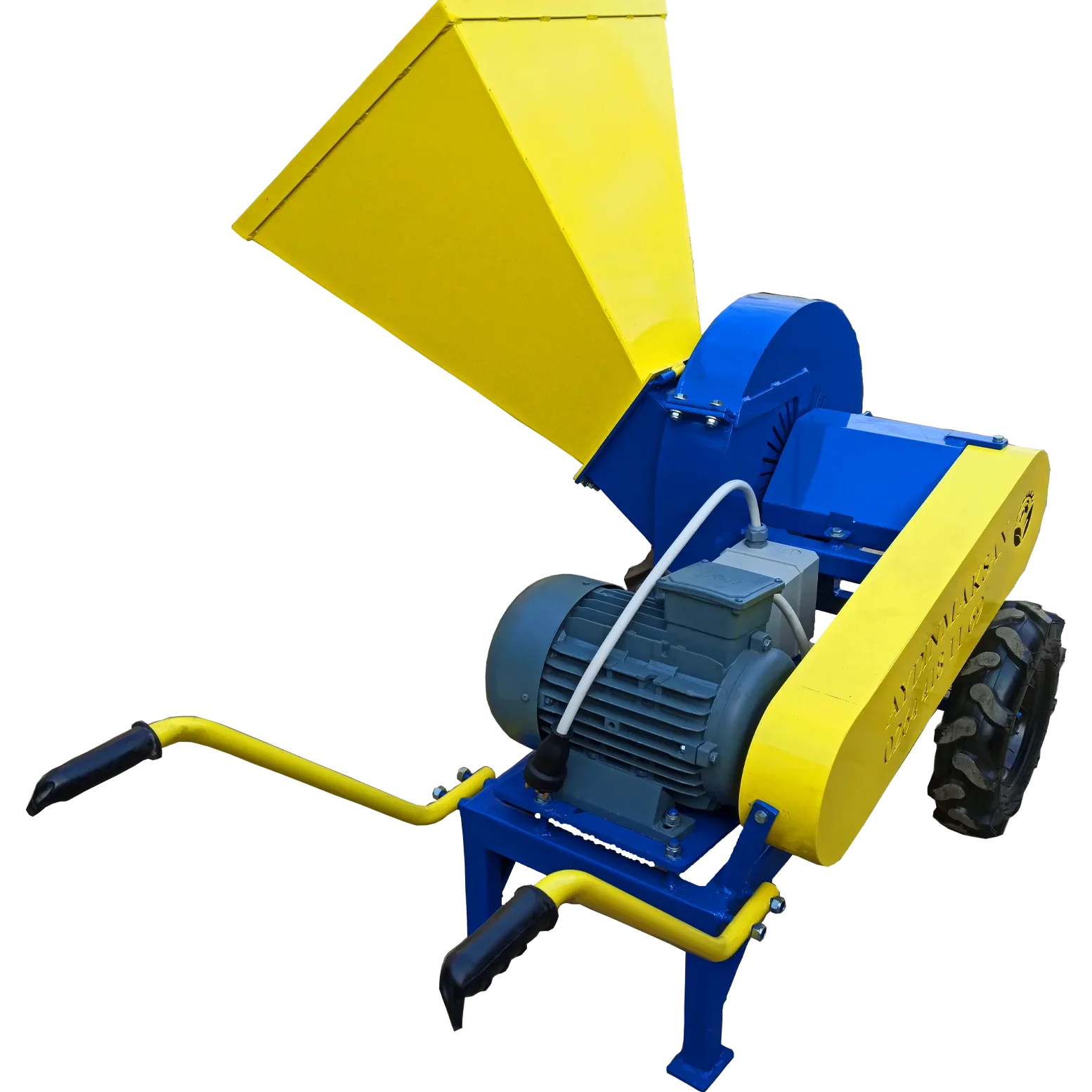

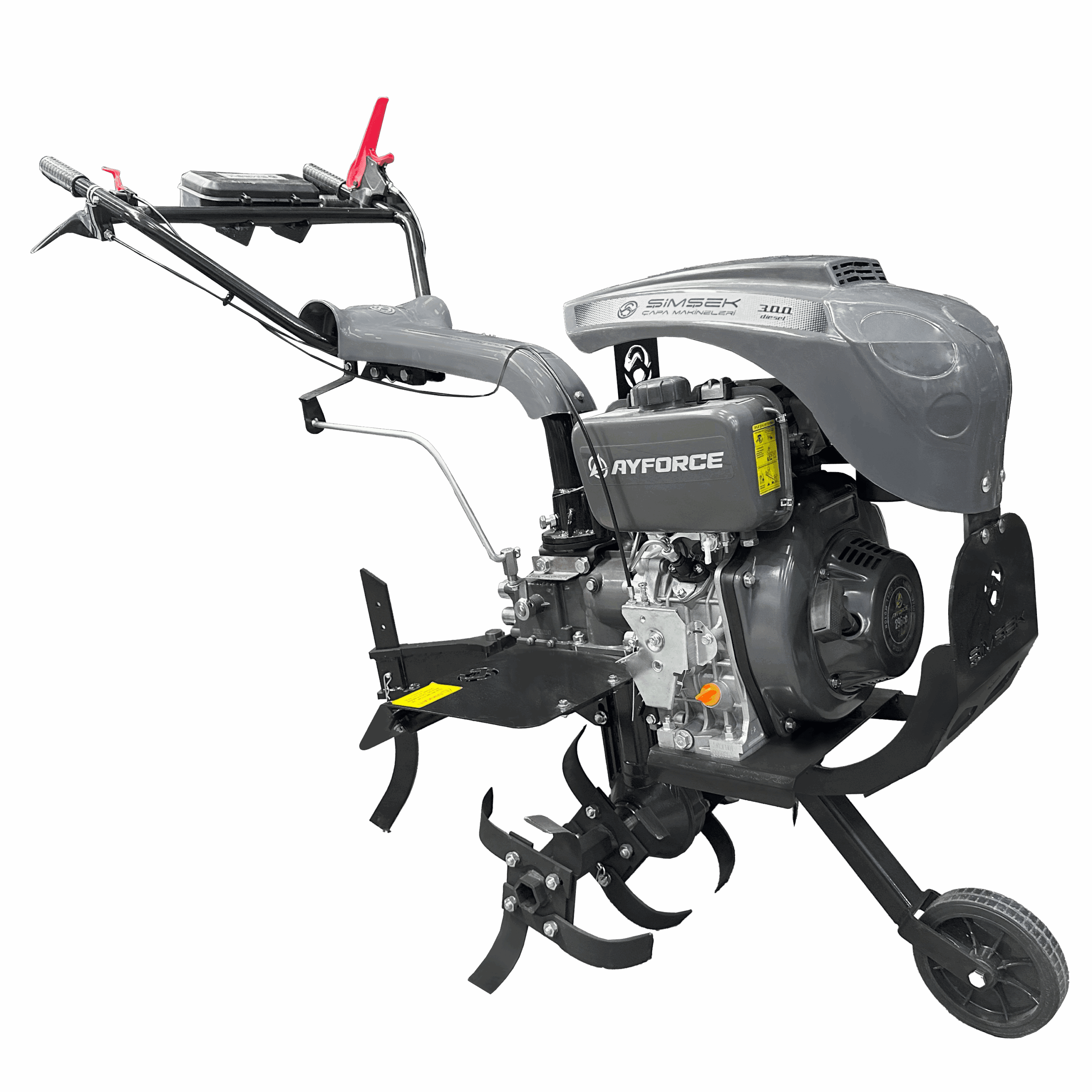

- Aydınmaksan Mobile Branch Grinding Machine Collected pruned tree branches, leaves, grass, twigs and other waste materials are broken down into small pieces and turned into wood chips.

Our products;

- MDO 009 – 9 HP Mobile Petrol-powered Branch Grinding Machine

- MDO 015A – 15 HP Fume-free Mobile Petrol-powered Branch Grinding Machine

- MDO 015B -15 HP Chimney-Equipped Mobile Petrol-Powered Branch Grinding Machine

Did you know that you can add our Electric Mobile Branch Shredders to your order as a special option?

- Our Aydınmaksan Industrial Branch Grinding Machine provides a professional solution for grinding pruned branches and workshop waste (wooden caps, slats, etc.). Thanks to the driven feeding system, the speed can be adjusted according to the thickness of the branches to be shredded, and during the feeding of the branches into the machine, the driven drum has the ability to change direction and stop instantly.

Our products;

- EDO 700 Electric Branch Grinder (13 cm diameter)

- EDO 700T Electric Wheel-Type Branch Grinder (13 cm diameter)

For detailed information, please contact our professional sales team.