Everything a grower needs to know about spraying equipment

You can apply chemical plant protection products with spraying machines (sprayers), also known as chemical spraying equipment. Spraying is a technique in which the pesticides to be applied are dissolved or suspended in water. This mixture can be applied as a mist on the product that needs protection by spraying machines. These machines are used to control all kinds of diseases, pests and fungi on plants.

Modern spraying machines (sprayers) have been developed to maximise spraying performance and prevent damage to crops. Spraying machines are used for various applications: herbicides, insecticides, disinfectants or fertilisers. The prices of plant protection equipment vary from low to high investments depending on the type of sprayer. The selection of the right sprayer depends on various factors: spray area size, spray application, fluid flow rate, fluid pressure, tank capacity, hose length, and the number of required spray nozzles.

What are the types of sprayers?

There are two types of spraying that you can use in greenhouses or farms: low-volume spraying techniques and high-volume spraying techniques. It is important to know that not every spraying technique is suitable for all products. Furthermore, not every product protection agent is suitable for every spraying technique. Therefore, it is important to know the differences between low-volume and high-volume spraying techniques.

Low-volume spraying technique: When the low-volume spraying technique is used, a small amount of spray liquid is used. This spraying technique is mostly preferred in the cultivation of potted plants and sometimes in vegetable cultivation.

High-volume spraying technique: Unlike the low-volume spraying technique, high-pressure spraying techniques use a large amount of spray liquid. Water containing dissolved plant protection products is distributed using a sprayer, boom sprayers, and spray guns or lances. High-pressure spraying techniques are used not only in floriculture but also in vegetable cultivation.

Advantages of Using Sprayers (Pulverisers)

Less visible residue. Crop protection products leave visible or invisible residues on crops. There is a legal standard for food crops: Maximum Residue Limit (MRL). This is to prevent people from ingesting harmful amounts when consuming the crop. When a visible residue is left on the product (fruit, flower or leaf), its (ornamental) value decreases. With field treatment, very little residue can be obtained on the product. On the other hand, visible residues sometimes form when spraying plant protection products.

Labour savings; products can be distributed over a large surface area in a short time. This method requires less labour than spraying, as it is not necessary to spray every centimetre of the plant’s path.

Less water usage. Fewer water is used with spraying machines (sprayers). The product’s quick drying reduces the likelihood of fungal infestation.

Types of spraying machine (sprayer) equipment:

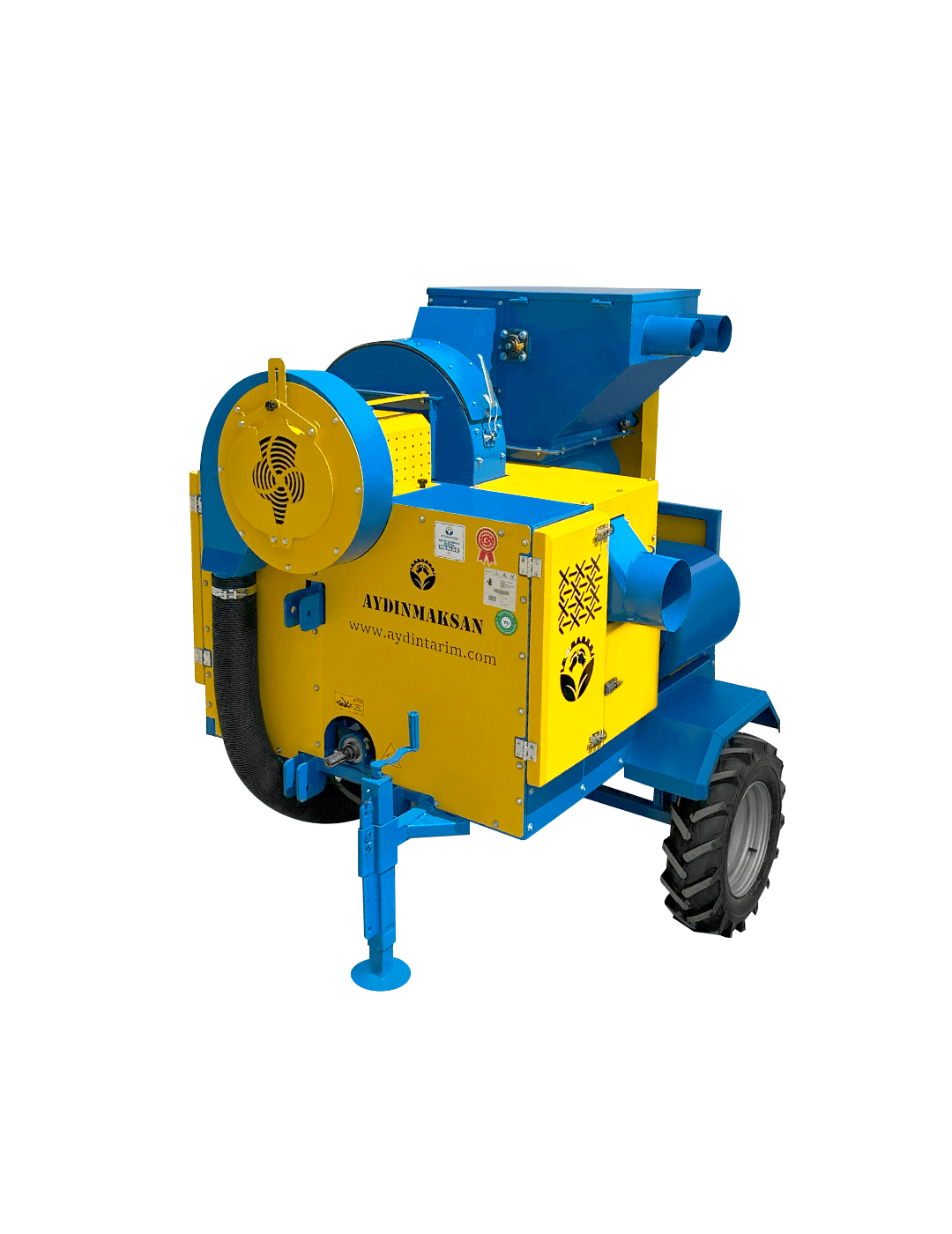

AYDINMAKSAN 400 LITRE 7 HP (SPRAYER) SPRAYING MACHINE (WITH 50 METRE HOSE AND GUN AS A GIFT)

- 50-metre hose and gun included as a gift.

- 30-litre pump

- LENGTH: 140 CM

- WIDTH: 96 CM

- HEIGHT: 140 CM

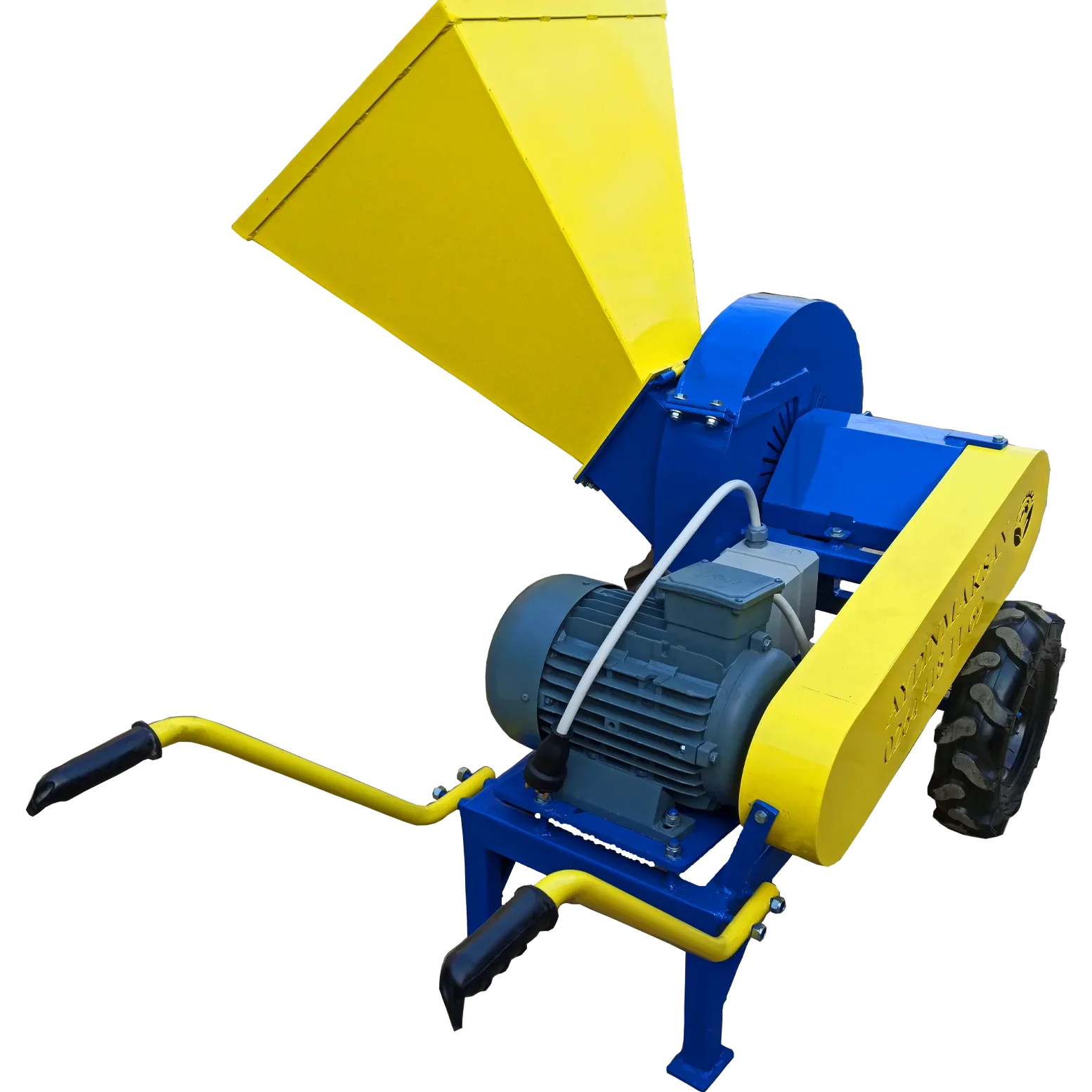

AYDINMAKSAN 200 LITRE 7 HP MOTORISED PETROL SPRAYER (50 METRE HOSE AND SPRAY GUN INCLUDED)

- 50-metre hose and gun included as a gift.

- 22-LITRE PUMP

- LENGTH: 158 CM

- WIDTH: 76 CM

AYDINMAKSAN 400 LITRE FAN-DRIVEN TURBO (SPRAYER) SPRAYING MACHINE

- HEIGHT: 140 CM

- WIDTH: 96 CM

- HEIGHT: 140 CM

AYDINMAKSAN 400 LITRE TRACTOR-MOUNTED (SPRAYER) SPRAYING MACHINE

- HEIGHT: 140 CM

- WIDTH: 96 CM

- HEIGHT: 140 CM

For detailed information about SPRAYING MACHINES, please contact our professional sales team.